H₂ Fuel Cell

Through the development of the Powertrain Control Unit and all embedded software, we are able to provide the integration of the fuel cell in your vehicle.

About H₂ Fuel cell

Dumarey Hydrocells’ dedicated Fuel Cell team is comprised of specialists across a range of different expertise, giving us the benefit of a comprehensive system architecture when it comes to: Energy Management System (EMS) control, Virtual Analysis, High Voltage/Low Voltage, Active Thermal Management and Total Cost of Ownership Analysis.

This allows Dumarey Hydrocells the flexibility to work with many different products and supply new integrated solutions or optimize existing ones.

Fuel Cell Products

Hybrid Propulsion Control Unit (HPCU) for Fuel Cell Powertrain & Embedded Advanced Control Software

Hybrid Propulsion Control Unit (HPCU) is the core controller which manages the full propulsion architecture for fuel cell hybrid vehicles. The in-house model-based embedded Software allows Dumarey Hydrocells to develop a customized solution and to control all the fuel cell propulsion subsystems. Embedded advanced control techniques, like Model Predictive Control (MPC), are used to optimize Energy and Thermal Management subsystems. Customized embedded Software can be even integrated into customer’s controller.

Main HW Controller features

Main SW Controller features

Energy Management System “MPC-based”, for optimizing electric power spilt between Fuel Cell and Battery: best trade off among efficiency and durability

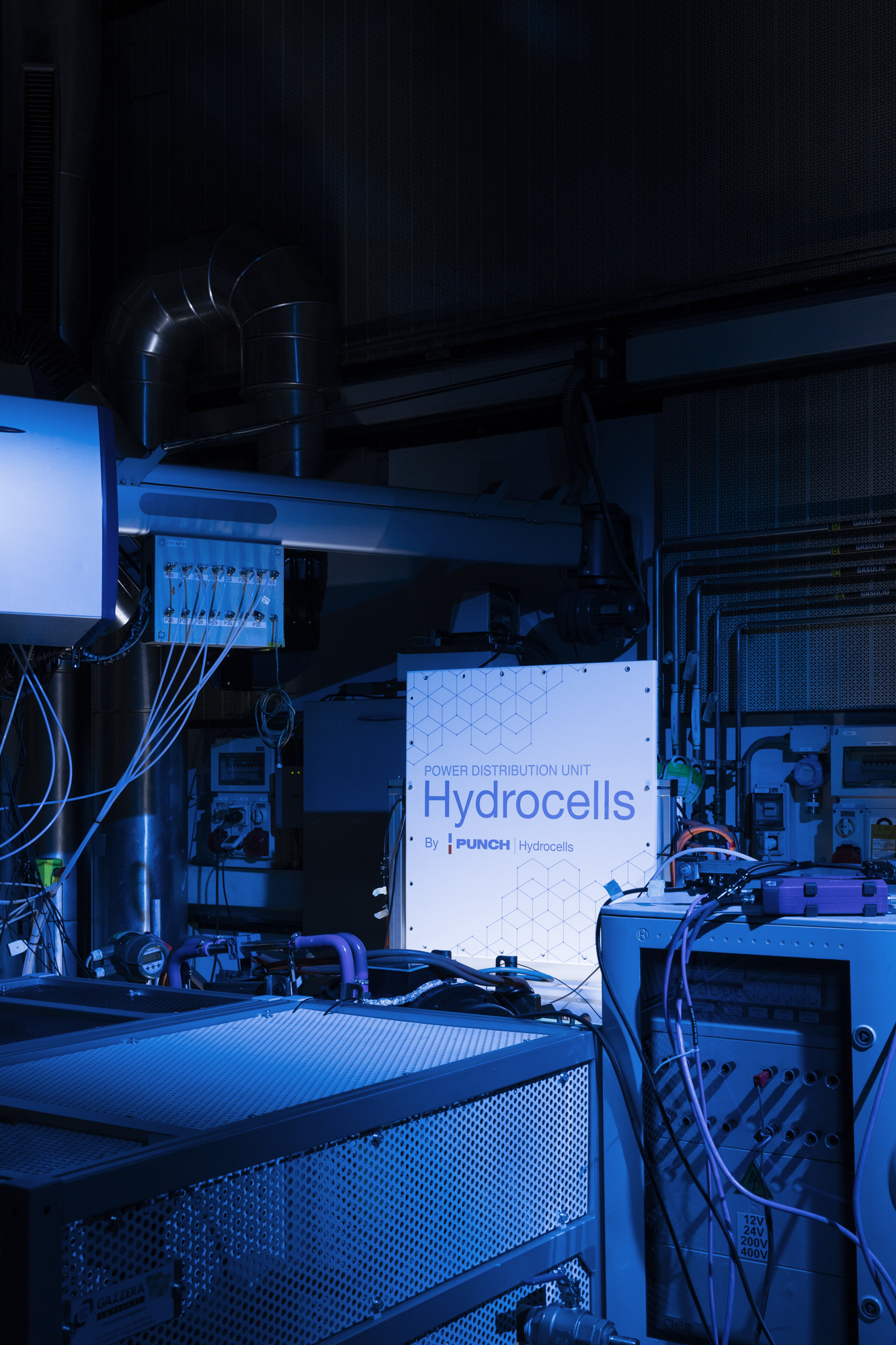

High Voltage/Low Voltage Modular Power Distribution Unit (Dumarey Hydrocells PDU)

Power Distribution Units in BEVs or FCEVs are used to distribute High Voltage between power supply (High-Voltage Battery or Fuel cells) and Loads (i.e. E-drive, Heaters etc). These are usually strongly customized based on application.

Dumarey Hydrocells Power Distribution Unit Modular, based on proprietary design, allows it to easily expands the number of High-Voltage I/O ports according to costumer’s requirements in terms of I/Os and packaging constrains.

Dumarey Hydrocells PDU embeds the capability to distribute and regulate different High Voltage levels (i.e. 700V-400V) and Low Voltage levels (i.e. 12V and 24V).

Service:

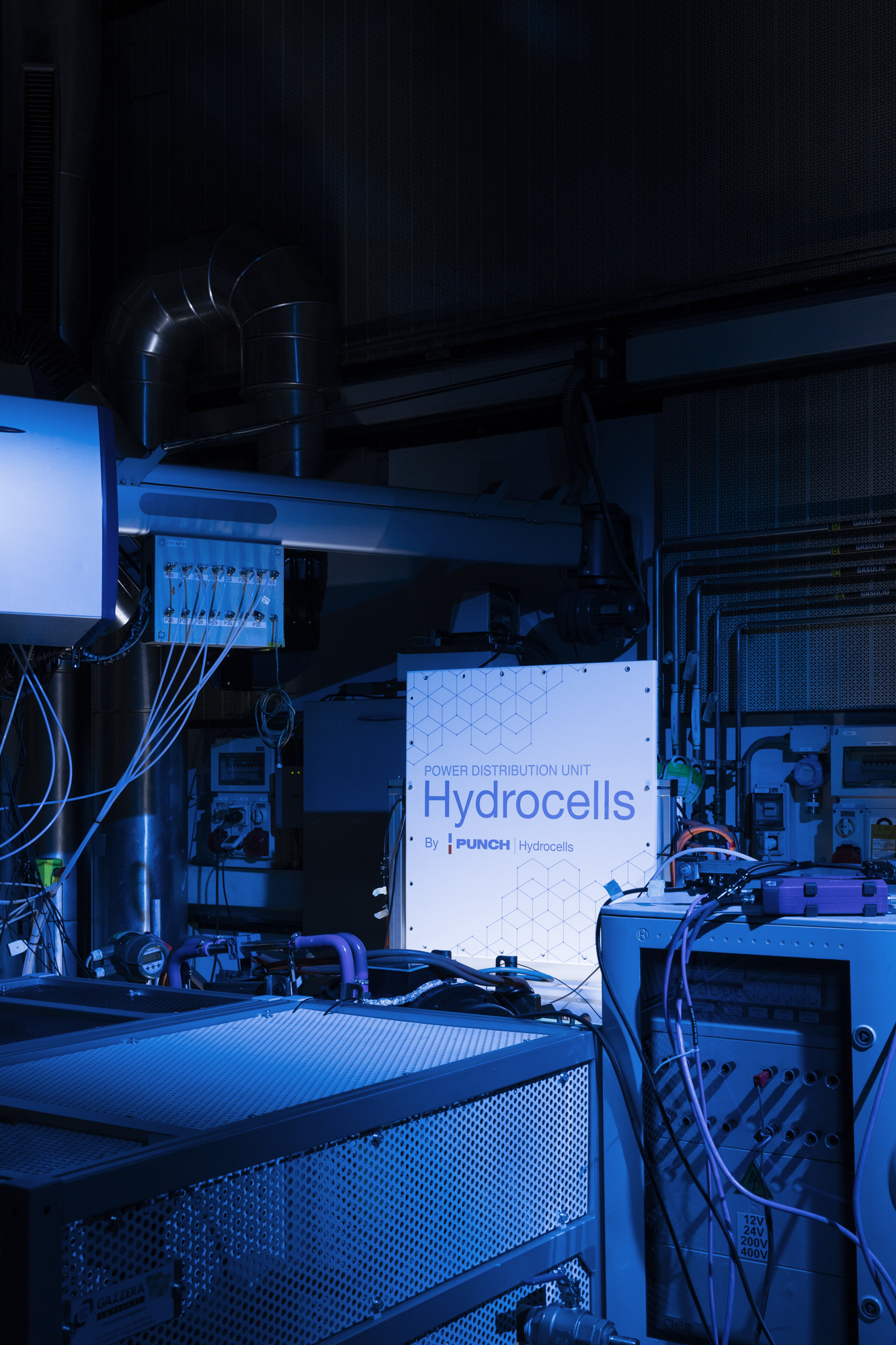

Fuel Cell Testing

The Fuel Cell Test Bench is fully modular and scalable: different power levels and powertrain architectures (HGV, Buses, Railways and others) can be tested and calibrated, including real driving cycle simulations, leading to a significant reduction of Vehicle Customer Development Time.

TECHNICAL SPECIFICATION:

1250 V DC link voltage

1000A output current bidirectional

Standard and custom battery model

INCA

Machinery directive complaint

Application specific Vehicle architecture safety concept

HORIBA High Dynamic 576 kW (30-55°C) & 125 kW (6-12°C)

5000rmp max speed

4 independent cooling circuits:

– High Temperature 100kW

– Medium Temperature 135kW

4 independent cooling circuits:

– High Temperature 100kW

– Medium Temperature 135kW

4 independent cooling circuits:

– High Temperature 100kW

– Medium Temperature 135kW

DCDs LV DCDC

800V 400v (35kW + 35kW)

12/24V

Combined or individual modes

Service:

Fuel Cell Testing

A “State of the Art” Fuel Cell Dyno bench is one of the first capable to manage multiple levels of high and low voltage, high quality Hydrogen fuel and up to two independent fuel cell systems. It features highly sophisticated and advanced cooling systems, all governed by a proprietary Powertrain Control Unit (PCU) Software which embeds at the same time.

One of the key benefits of our Fuel Cell Test Bench is that it is fully modular and scalable: different power levels and powertrain architectures (such as HGV, buses, railways and others) are able to be tested and calibrated, including real driving cycle simulations. This leads to a significant reduction of Vehicle Customer development time.

TECHNICAL SPECIFICATION:

1250 V DC link voltage

1000A output current bidirectional

Standard and custom battery model

INCA

Machinery directive complaint

Application specific Vehicle architecture safety concept

HORIBA High Dynamic 576 kW (30-55°C) & 125 kW (6-12°C)

5000rmp max speed

installed capability 280 kW (30-55°C) & 125 (6-12°C) to manage 4 independent cooling circuits

H2 flow meter AVL Hytron:

-Up to 25bar

-Up to 30 kg/h

In house Power distribution units, HV

DCDs LV DCDC

800V

400V (35kW + 35kW)

12/24V

Combined or individual modes

Fuel Cell Test Dyno Bench - Brochure

Key benefits of the Dyno Bench

Module testing

Up 2 FC module testing (Single/Double)

Time

Development time reduction

Simulation

Real-time system simulation & validation – Run certification cycles

Durability

24/7 Durability validation test from component to system vehicle

Flexibility

Flexible and modular layout

Testing

Test full powertrain system

Minimization of hydrogen consumption

Minimization of hydrogen consumption based on different vehicle characteristics

Optimization

Optimization of cost vs performances: lifetime components maximization

Case studies

Publicly available articles & papers

Development of a Total Cost of Ownership Model to Compare BEVs, FCEVs and Diesel Powertrains on Bus Applications

This paper develops a bottom-up cost methodology to evaluate the Total Cost of Ownership (TCO) of a12-Meter city BUS, that can be applied to different Hardware/Powertrain/Fuel/Market combinations.

Evaluation of the impact of different Active Thermal Management System layouts on medium/heavy duty FCEVs performance

This paper presents the analysis of different cooling circuit architectures on H2 consumption for a Fuel Cell-based urban Bus.

Evaluation of the Optimal Thermal Energy distribution layouts on medium/heavy duty FCEVs

This publication presents a detailed optimization activity of the thermal energy distribution between sources and sinks, aimed to minimize the energy consumption on a specific H2 Fuel Cell-based urban Bus.

Optimal Control of a Fuel Cell Electric Vehicle (FCEV) Powertrain

This paper proposes a Model Predictive Controller (MPC) for the optimal operations of a fuel cell / battery hybrid powertrain applied to a city bus. The proposed real-time MPC strategy has been designed to optimize the trade-off among hydrogen consumption, battery state of charge (SOC) dynamics, fuel cells and battery power smoothness, while guaranteeing the fulfilment of all required constraints.

Download this paper

Hydrogen Moto-propulsion: the Fuel Cells

This paper discusses the fundamentals of H2 technology and its use within a powertrain based on a PEM-type FC.